Ondřej Kašpar

Post-doctoral researcher

Ph.D. University of Chemistry and Technology Prague, Czech Republic

M.Sc. University of Chemistry and Technology Prague, Czech Republic

![]() former member of Chobotix group

former member of Chobotix group

Pavillon des Sciences Biologiques

McGill Bioengineering department, room SB-5585 (5th floor)

141 Avenue du Président-Kennedy

Montréal, QC H2X 1Y4

![]()

![]()

![]()

Publications

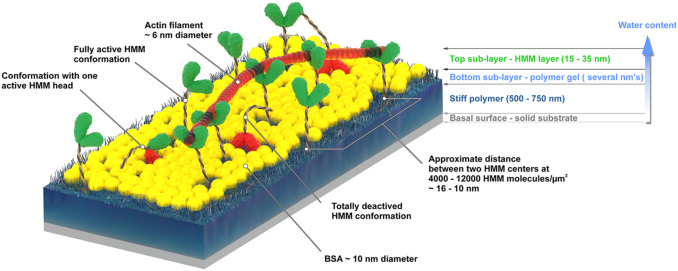

Hanson, K. L., Fulga, F., Dobroiu, S., Solana, G., Kašpar, O., Tokárová, V., Nicolau, D. V., "Polymer surface properties control the function of heavy meromyosin in dynamic nanodevices", Biosensors and Bioelectronics (2016) MoreLess

The actin-myosin system, responsible for muscle contraction, is also the force-generating element in dynamic nanodevices operating with surface-immobilized motor proteins. These devices require materials that are amenable to micro- and nano-fabrication, but also preserve the bioactivity of molecular motors. The complexity of the protein-surface systems is greatly amplified by those of the polymer-fluid interface; and of the structure and function of molecular motors, making the study of these interactions critical to the success of molecular motor-based nanodevices. We measured the density of the adsorbed motor protein (heavy meromyosin, HMM) using quartz crystal microbalance; and motor bioactivity with ATPase assay, on a set of model surfaces, i.e., nitrocellulose, polystyrene, poly(methyl methacrylate), and poly(butyl methacrylate), poly(tert-butyl methacrylate). A higher hydrophobicity of the adsorbing material translates in a higher total number of HMM molecules per unit area, but also in a lower uptake of water, and a lower ratio of active per total HMM molecules per unit area. We also measured the motility characteristics of actin filaments on the model surfaces, i.e., velocity, smoothness and deflection of movement, determined via in vitro motility assays. The filament velocities were found to be controlled by the relative number of active HMM per total motors, rather than their absolute surface density. The study allowed the formulation of the general engineering principles for the selection of polymeric materials for the manufacturing of dynamic nanodevices using protein molecular motors.

The actin-myosin system, responsible for muscle contraction, is also the force-generating element in dynamic nanodevices operating with surface-immobilized motor proteins. These devices require materials that are amenable to micro- and nano-fabrication, but also preserve the bioactivity of molecular motors. The complexity of the protein-surface systems is greatly amplified by those of the polymer-fluid interface; and of the structure and function of molecular motors, making the study of these interactions critical to the success of molecular motor-based nanodevices. We measured the density of the adsorbed motor protein (heavy meromyosin, HMM) using quartz crystal microbalance; and motor bioactivity with ATPase assay, on a set of model surfaces, i.e., nitrocellulose, polystyrene, poly(methyl methacrylate), and poly(butyl methacrylate), poly(tert-butyl methacrylate). A higher hydrophobicity of the adsorbing material translates in a higher total number of HMM molecules per unit area, but also in a lower uptake of water, and a lower ratio of active per total HMM molecules per unit area. We also measured the motility characteristics of actin filaments on the model surfaces, i.e., velocity, smoothness and deflection of movement, determined via in vitro motility assays. The filament velocities were found to be controlled by the relative number of active HMM per total motors, rather than their absolute surface density. The study allowed the formulation of the general engineering principles for the selection of polymeric materials for the manufacturing of dynamic nanodevices using protein molecular motors.

Kašpar, O., Zhang, H., Tokárová, V., Boysen, R. I., Suñé, G. R., Borrise, X., Murano, F.P., Hearn, M. T. W., Nicolau, D.V., "Confinement of water droplets on rectangular micro/nano-arrayed surfaces", Lab Chip, 16, 2487-2493 (2016) MoreLess

Filipponi, L., Livingston, P., Kašpar, O., Tokárová, V., Nicolau, D.V., "Protein patterning by microcontact printing using pyramidal PDMS stamps", Biomedical Microdevices 18, 1-7 (2016) MoreLess

Micro-contact printing, μCP, is a well-established soft-lithography technique for printing biomolecules. μCP uses stamps made of Poly(dimethylsiloxane), PDMS, made by replicating a microstructured silicon master fabricated by semiconductor manufacturing processes. One of the problems of the μCP is the difficult control of the printing process, which, because of the high compressibility of PDMS, is very sensitive to minute changes in the applied pressure. This over-sensitive response leads to frequent and/or uncontrollable collapse of the stamps with high aspect ratios, thus decreasing the printing accuracy and reproducibility. Here we present a straightforward methodology of designing and fabricating PDMS structures with an architecture which uses the collapse of the stamp to reduce, rather than enlarge the variability of the printing. The PDMS stamp, organized as an array of pyramidal micro-posts, whose ceiling collapses when pressed on a flat surface, replicates the structure of the silicon master fabricated by anisotropic wet etching. Upon application of pressure, depending on the size of, and the pitch between, the PDMS pyramids, an air gap is formed surrounding either the entire array, or individual posts. The printing technology, which also exhibits a remarkably low background noise for fluorescence detection, may find applications when the clear demarcation of the shapes of protein patterns and the distance between them are critical, such as microarrays and studies of cell patterning.

Micro-contact printing, μCP, is a well-established soft-lithography technique for printing biomolecules. μCP uses stamps made of Poly(dimethylsiloxane), PDMS, made by replicating a microstructured silicon master fabricated by semiconductor manufacturing processes. One of the problems of the μCP is the difficult control of the printing process, which, because of the high compressibility of PDMS, is very sensitive to minute changes in the applied pressure. This over-sensitive response leads to frequent and/or uncontrollable collapse of the stamps with high aspect ratios, thus decreasing the printing accuracy and reproducibility. Here we present a straightforward methodology of designing and fabricating PDMS structures with an architecture which uses the collapse of the stamp to reduce, rather than enlarge the variability of the printing. The PDMS stamp, organized as an array of pyramidal micro-posts, whose ceiling collapses when pressed on a flat surface, replicates the structure of the silicon master fabricated by anisotropic wet etching. Upon application of pressure, depending on the size of, and the pitch between, the PDMS pyramids, an air gap is formed surrounding either the entire array, or individual posts. The printing technology, which also exhibits a remarkably low background noise for fluorescence detection, may find applications when the clear demarcation of the shapes of protein patterns and the distance between them are critical, such as microarrays and studies of cell patterning.

Oka S., Emady H., Kašpar O., Tokárová V., Muzzio F.J., Štěpánek F., Ramachandran R., “The effects of improper mixing and preferential wetting of active and excipient ingredients on content uniformity in high shear wet granulation”, Powder Technol. 278, 266-277 (2015) MoreLess

This work focuses on the content non-homogeneity in granules across size classes in a high shear wet granulation process as a result of powder segregation during dry mixing coupled with preferential wettability of one of the ingredients with the binder fluid.

This work focuses on the content non-homogeneity in granules across size classes in a high shear wet granulation process as a result of powder segregation during dry mixing coupled with preferential wettability of one of the ingredients with the binder fluid.

A two component API-excipient system comprised of acetaminophen (APAP) and microcrystalline cellulose PH-101 (MCC) is investigated in a high shear granulation environment for content uniformity of the granules with respect to APAP. It was found that the fine granules were super potent while the coarse granules were starved of the APAP. This was attributed to a dual cause of powder segregation during dry mixing and superior wettability of the MCC compared to APAP. Post the dry mixing stage, the top layer of the powder bed is found to be sub-potent due to percolation of the smaller APAP particles to the bottom of the bed as they find spaces between the larger MCC particles. Thus, a drop of the binder fluid which falls on the bed is likely to be surrounded by MCC particles, which give them a higher chance of being incorporated in the nucleus. Moreover, MCC being the superior wetting of the two ingredients, also preferentially attaches itself to the growing granules. The granules are thus starved of the APAP leading to disparity in content across size classes.

Lastly, the effect of content non-uniformity was categorically quantified on the rate of active release. It was observed that content non-uniformity results in a lack of predictability and consequently control, on the rate of release of the active ingredient from the granules. This work highlights the need for qualitative understanding and quantitative analysis of factors that contribute to the occurrence of granule content non-uniformity, if one is to enable inherently robust pharmaceutical product design.

Oka S., Kašpar O., Tokárová V., Sowrirajan K., Wu H., Khan H., Muzzio F., Štěpánek F., Ramachandran R., “A quantitative study of the effect of process parameters on key granule characteristics in a high shear wet granulation process”, Adv. Powder Technol. 26, 315-322 (2015) MoreLess

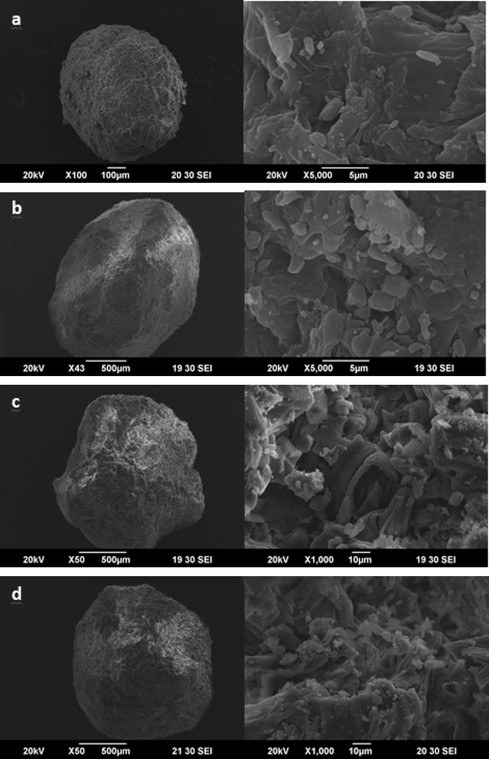

The objective of the current work was to investigate the effect of liquid to solid ratio (L/S), impeller speed and the wet massing time on the critical quality attributes of granules in a high shear wet granulation process for a two component (API and excipient) system. The parameters were evaluated for their effect on granule properties using a design of experiment based approach. Granules were characterized for their particle size distribution, content uniformity, morphology and porosity. The liquid to solid (L/S) ratio was found to have a dominant effect on the median particle size and exhibited a clear trend. The system was found to be extremely well mixed for all conditions thus implying robust composition uniformity within and between batches, independent of process parameters. The release kinetics of granules within the batch were found to be identical, independent of particle size. The granules were found to be fairly spherical as observed through a scanning electron microscope with no distinct agglomeration. The images indicate granulation by layering and consolidation. All three process parameters were found to have an effect on granule porosity, with the wet massing time having the most pronounced effect. A judicious selection of the afore mentioned process parameters will enable a balance between granule growth and porosity to be achieved without compromising on the mixing efficiency of the process thereby allowing one to build quality into the final product.

The objective of the current work was to investigate the effect of liquid to solid ratio (L/S), impeller speed and the wet massing time on the critical quality attributes of granules in a high shear wet granulation process for a two component (API and excipient) system. The parameters were evaluated for their effect on granule properties using a design of experiment based approach. Granules were characterized for their particle size distribution, content uniformity, morphology and porosity. The liquid to solid (L/S) ratio was found to have a dominant effect on the median particle size and exhibited a clear trend. The system was found to be extremely well mixed for all conditions thus implying robust composition uniformity within and between batches, independent of process parameters. The release kinetics of granules within the batch were found to be identical, independent of particle size. The granules were found to be fairly spherical as observed through a scanning electron microscope with no distinct agglomeration. The images indicate granulation by layering and consolidation. All three process parameters were found to have an effect on granule porosity, with the wet massing time having the most pronounced effect. A judicious selection of the afore mentioned process parameters will enable a balance between granule growth and porosity to be achieved without compromising on the mixing efficiency of the process thereby allowing one to build quality into the final product.

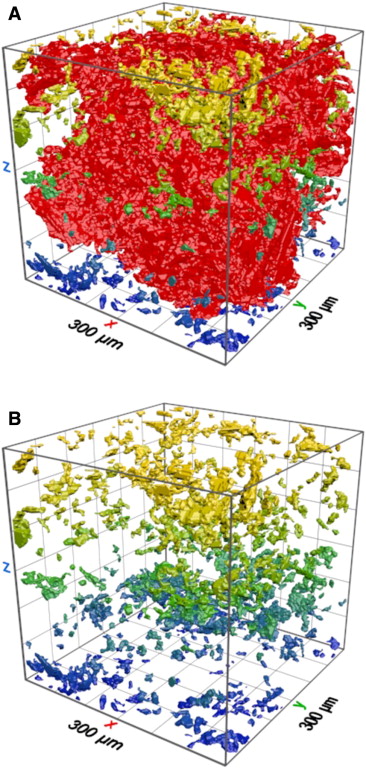

Kašpar O., Tokárová V., Oka S., Sowrirajan K., Ramachandran R., Štěpánek F., “Combined UV/Vis and micro-tomography investigation of acetaminophen dissolution from granules”, Int. J. Pharm. 458, 272-281 (2013) MoreLess

The X-ray micro-tomography (micro-CT) technique has been used to visualize the microstructure of granules produced by high shear wet granulation and the dynamic evolution of porosity during granule dissolution. Using acetaminophen (paracetamol) as the active pharmaceutical ingredient (API) and microcrystalline cellulose (Avicel PH-200) as an excipient, the porosity of the granules was systematically influenced by the granulation process parameters (binder/solids ratio, impeller speed and wet massing time). An increase of granule porosity from 7% to 10% and 18% lead to a decrease of the dissolution time t90 from 435 min to 98 min and 37 min, respectively. The combination of time-resolved micro-CT imaging with UV/vis detection of the quantity dissolved made it possible to evaluate the effective diffusion coefficient of the API through the granule structure, and thus establish a quantitative structure–property relationship for dissolution. A power-law dependence of the effective diffusivity on porosity (Archie's law) was found to hold.

The X-ray micro-tomography (micro-CT) technique has been used to visualize the microstructure of granules produced by high shear wet granulation and the dynamic evolution of porosity during granule dissolution. Using acetaminophen (paracetamol) as the active pharmaceutical ingredient (API) and microcrystalline cellulose (Avicel PH-200) as an excipient, the porosity of the granules was systematically influenced by the granulation process parameters (binder/solids ratio, impeller speed and wet massing time). An increase of granule porosity from 7% to 10% and 18% lead to a decrease of the dissolution time t90 from 435 min to 98 min and 37 min, respectively. The combination of time-resolved micro-CT imaging with UV/vis detection of the quantity dissolved made it possible to evaluate the effective diffusion coefficient of the API through the granule structure, and thus establish a quantitative structure–property relationship for dissolution. A power-law dependence of the effective diffusivity on porosity (Archie's law) was found to hold.

Kašpar O., Tokárová V., Nyanhongo G. S., Gübitz G., Štěpánek F., “Effect of cross-linking method on the activity of spray-dried chitosan microparticles with immobilized laccase”, Food Bioprod. Proces. 91, 525-533 (2013) MoreLess

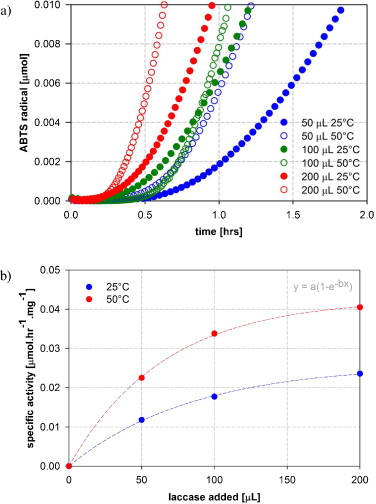

The effect of processing method on the properties of cross-linked chitosan microparticles and on the enzymatic activity of laccase immobilized in the particles has been investigated. Chitosan has been cross-linked by tri-polyphosphate (TPP) using two methods – the so called ex situ cross-linking whereby the solutions of chitosan, TPP and the enzyme have been pre-mixed and spray-dried by a standard two-fluid kinetic nozzle, and a novel in situ cross-linking method, whereby the solutions have been contacted at the tip of a three-fluid nozzle and cross-linking occurred within a drying droplet. The influence of the cross-linking method on the particle size and morphology, surface charge, and swelling ratio has been determined. The enzymatic activity of laccase toward the oxidation of a chromophore substrate (ABTS) has been systematically investigated and found to be superior in particles produced by the in situ cross-linking method.

The effect of processing method on the properties of cross-linked chitosan microparticles and on the enzymatic activity of laccase immobilized in the particles has been investigated. Chitosan has been cross-linked by tri-polyphosphate (TPP) using two methods – the so called ex situ cross-linking whereby the solutions of chitosan, TPP and the enzyme have been pre-mixed and spray-dried by a standard two-fluid kinetic nozzle, and a novel in situ cross-linking method, whereby the solutions have been contacted at the tip of a three-fluid nozzle and cross-linking occurred within a drying droplet. The influence of the cross-linking method on the particle size and morphology, surface charge, and swelling ratio has been determined. The enzymatic activity of laccase toward the oxidation of a chromophore substrate (ABTS) has been systematically investigated and found to be superior in particles produced by the in situ cross-linking method.

Tokárová V., Kašpar O., Knejzlík Z., Ulbrich P., Štěpánek F., “Development of spray-dried chitosan microcarriers for nanoparticle delivery”, Powder Technol. 235, 797-805 (2013) MoreLess

The design of chitosan microspheres for the encapsulation and release of nanoparticles has been considered. The composite microcarriers have been produced by spray drying and the effect of factors including the chitosan cross-linking ratio (using tri-polyphosphate as the cross-linking agent), nanoparticle loading in the polymer matrix and the internal structure of the microspheres (uniform dispersion of nanoparticles vs. core-shell structure) on the in vitro release kinetics have been systematically investigated. The antibacterial performance of the composite microspheres containing Ag nanoparticles has been evaluated against three different strains of bacteria in a suspension culture. The bioadhesive character of the chitosan carrier particles has lead to the formation of stable aggregates with the bacteria, which enhanced the antibacterial efficacy of the released nanoparticles through the contact mechanism.

The design of chitosan microspheres for the encapsulation and release of nanoparticles has been considered. The composite microcarriers have been produced by spray drying and the effect of factors including the chitosan cross-linking ratio (using tri-polyphosphate as the cross-linking agent), nanoparticle loading in the polymer matrix and the internal structure of the microspheres (uniform dispersion of nanoparticles vs. core-shell structure) on the in vitro release kinetics have been systematically investigated. The antibacterial performance of the composite microspheres containing Ag nanoparticles has been evaluated against three different strains of bacteria in a suspension culture. The bioadhesive character of the chitosan carrier particles has lead to the formation of stable aggregates with the bacteria, which enhanced the antibacterial efficacy of the released nanoparticles through the contact mechanism.

Kašpar O., Jakubec M., Štěpánek F., “Characterization of spray dried chitosan-TPP microparticles formed by two- and three-fluid nozzles”, Powder Technol. 240, 31-40 (2013) MoreLess

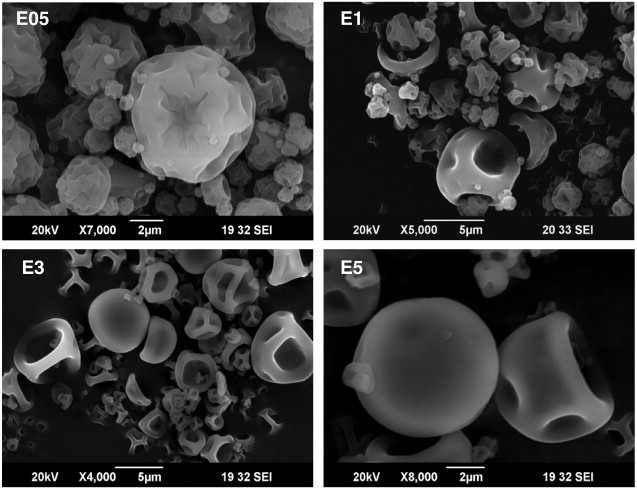

Chitosan microparticles cross-linked by tri-polyphosphate (TPP) anions have been prepared by spray drying. Two different cross-linking methods have been employed — ex-situ cross-linking whereby aqueous solution of cross-linked chitosan nanoparticles has been spray-dried by a two-fluid nozzle, and a novel in-situ cross-linking method, whereby solutions of chitosan and TPP have been fed to a three-fluid nozzle and cross-linking occurred within individual droplets. The size and morphology of the resulting microparticles have been characterised and their dependence on the cross-linking ratio and the initial chitosan concentration determined. Particles produced by the three-fluid nozzle were found to have favourable properties in terms of stability in aqueous media and they allow the use of higher chitosan concentrations, which makes them suitable for microencapsulation applications.

Chitosan microparticles cross-linked by tri-polyphosphate (TPP) anions have been prepared by spray drying. Two different cross-linking methods have been employed — ex-situ cross-linking whereby aqueous solution of cross-linked chitosan nanoparticles has been spray-dried by a two-fluid nozzle, and a novel in-situ cross-linking method, whereby solutions of chitosan and TPP have been fed to a three-fluid nozzle and cross-linking occurred within individual droplets. The size and morphology of the resulting microparticles have been characterised and their dependence on the cross-linking ratio and the initial chitosan concentration determined. Particles produced by the three-fluid nozzle were found to have favourable properties in terms of stability in aqueous media and they allow the use of higher chitosan concentrations, which makes them suitable for microencapsulation applications.